- Tesla is actively working on scaling up production of the innovative 4680 battery to meet strong demand for the Cybertruck.

- Tesla currently operates only two production lines for 4680 batteries but plans to expand to eight lines at Gigafactory Texas, indicating a commitment to growth and overcoming challenges

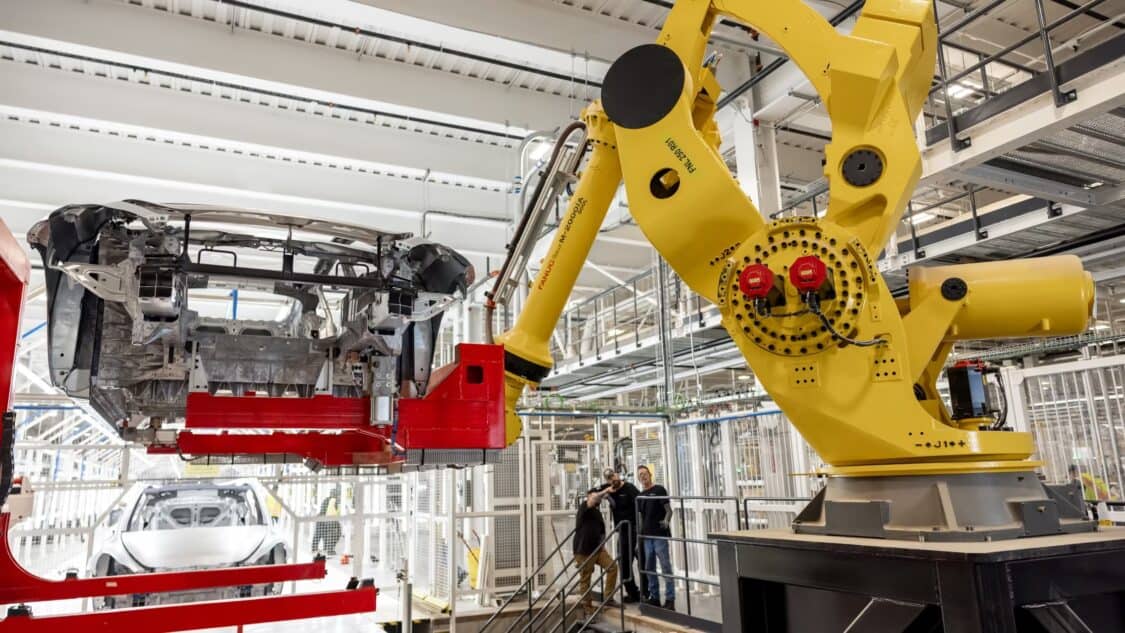

- Tesla’s 4680 battery cells not only power the Cybertruck but also serve as a structural component of the vehicle’s frame, reducing the need for welding and cutting production costs.

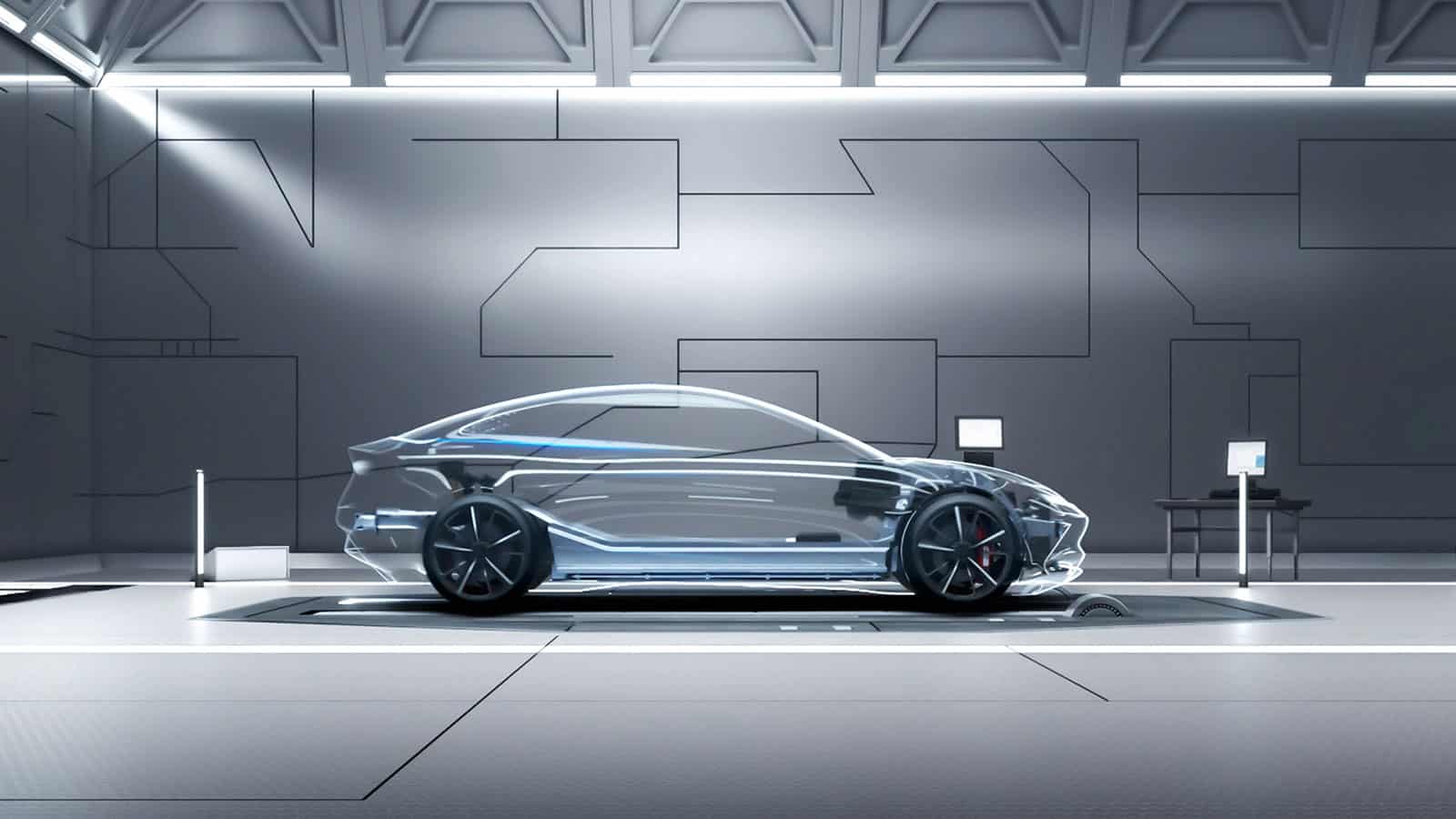

Tesla has gained recognition for its pioneering 4680 battery technology. This advanced battery not only provides energy for the highly anticipated Cybertruck but also seeks to bring innovation to the electric vehicle sector as a whole. However, Tesla has encountered difficulties when attempting to increase production at scale. Is Tesla trying too much too soon? And will the EV giant get close to making good on its Cybertruck annual production promises?

The Innovative 4680 Battery

When Tesla announced the production of the controversial 2024 Cybertruck, the automaker shared the benefits about the new 4680 cells. These large cells do more than power the truck; they act as part of the truck’s frame. Thanks to this innovative design, the 4680 battery requires less welding – resulting in lower production costs.

ADVERTISEMENT

Another money-saving innovation lies in the battery’s “dry-coating” process. Most EV batteries have a “wet-coating” process that requires a slow, methodical wet mixture that covers the anode and cathode. Once those components are covered, they are baked to set the wet coating in place. Dry coating is quick and has fewer steps – making the process more affordable.

Herein Lies The Rub

Despite the speedy dry-coating process, Tesla tragically cannot make the batteries fast enough. Even though Elon Musk claimed to hold Cybertruck production to 250,000 annually, his company is barely eking out 2,000 trucks monthly.

The problem: Tesla can’t make enough 4680 batteries. Each Cybertruck needs 1,360 cells, and the automaker is only making enough each month to fill about 2,000 vehicles.

Tesla is still developing the dry-coating technology and appears to be figuring things out as they go. This isn’t just a problem for future Cybertruck owners who have to wait longer, it could be a problem for current owners who could end up with subpar battery technology.

The battery technology requires a Teflon binder without moisture to hold the lithium, nickel, and other materials together. Tesla is finding that the mixing process gets too hot, and then the Teflon binder melts. At the start of the process, Tesla was disposing of up to 30% of the product. Previous battery manufacturing had a 5% scrap rate, and Tesla is working to bring the 4680 scrap rate down to 20% or lower.

Difficulty Finding the Truth

Tesla isn’t known for sharing manufacturing details. Rumor has it the original plan for the dry-coated 4680 batteries was to use them in the Model Y. Instead, Tesla is putting its tried-and-true Panasonic 2170 batteries in the Model Y. Insiders speculate that Tesla is saving any and all 4680 batteries for the Cybertruck.

ADVERTISEMENT

While working on the 4680, Tesla managed to alter the battery chemistry to increase power density. If they put the 4680 battery in the Model Y, the automaker would have to develop a new range variant. Standard-Range. Long-Range. Ludicrous-Range?

Too Much. Too Soon.

According to Drew Baglino, SVP of Engineering, the automaker plans to have eight lines of 4680 production at Gigafactory Texas. Currently, the automaker only has two lines, and they’re moving at a snail’s pace.

In 2020, Tesla claimed the 4680 batteries would cut battery production costs in half, which would also result in smaller, eco-friendly manufacturing facilities. Unfortunately, Tesla seems to have made its claim based on prototypes, and the EV giant can’t get the technology to an industrial scale.

The struggle for Tesla lies in trying to do too many things at once. Releasing the Cybertruck put pressure on a system that wasn’t “ready for prime time,” as Tesla is trying to scale while also developing the tools and equipment.

Along with the battery manufacturing issues, Tesla is also busy negotiating with Mexico to build a new factory to make the 4680 batteries and Cybertruck. According to Nuevo León Governor Samuel Garcia Sepulveda, Tesla continues to change the plans for the factory, making it up to three times bigger than originally planned. The constant changes show how ill-prepared Tesla is to manufacture the Cybertruck and its vital components.

Tesla’s Ambitious Goals vs. 4680 Battery Production Realities

With each Cybertruck needing 1,360 cells, Tesla will need to make approximately one million 4680 battery cells daily to achieve the annual goal of 250,000 Cybertrucks. Currently, the Austin factory is making about 10 million cells every four months, which is about 32.5 million cells annually – well below the 340 million needed to achieve Musk’s lofty Cybertruck goal.

The automaker doesn’t just want to use the 4680 in the Cybertruck. It wants to put the more efficient battery in the upcoming $25,000 Tesla Model 2. This small Tesla is expected to arrive sometime in the mid-2020s and be a serious competitor thanks to its sub-$30,000 sticker price.

As Tesla struggles to get the 4680 battery production under control, other automakers are pushing more electric pickups into the competitive market. The Ford F150 Lightning started the trend, and the rest of the Big Three are following it with the Chevrolet Silverado EV, the GMC Sierra EV, and the GMC Hummer EV. Rivian’s R1T has turned out to be a popular option, and Stellantis will soon release the Ram REV which is sure to be loaded with luxurious and innovative features.

If Tesla can’t produce the batteries, the automaker won’t be able to deliver against the competition. No batteries = no EVs.

However, if Tesla can scale the battery production, it will be a major game-changer requiring less time, energy, and raw materials.

A Big Ball of Goo

When Tesla attempted to scale the new dry-coated batteries, the heated Teflon turned the blend into a gooey mess. The automaker is also finding it challenging to prepare the metallic foil for the battery electrodes. The massive rollers that are moving the foil (think of newspaper printing machines) are applying uneven pressure, causing more batteries to become scrap.

The heat and foil issues are pushing Tesla to develop a new quality verification system. Unfortunately, this technology isn’t working as Tesla expected. While building necessary data, Tesla is finding that the dry-coating is hiding the flaws with problems showing up months after production.

Are the battery flaws going to show up in the Cybertrucks that are already on the road? Possibly, as the automaker doesn’t know which cells are good or bad. Fortunately, the Tesla has a four-year/50,000-mile vehicle warranty and an eight-year/100,000-mile battery and drive unit warranty.

I’d wait on those after-market Cybertruck modifications to protect the federally mandated eight-year EV battery warranty.

ADVERTISEMENT

IMAGES: TESLA, ELECTRIFY EXPO

FTC: We use income-earning auto affiliate links. Learn more.

2 Responses