- BorgWarner announces eTVD system, improves EV stability and performance.

- eTVD replaces differential, integrating torque vectoring.

- BorgWarner offers OEMs customizable eTVD software.

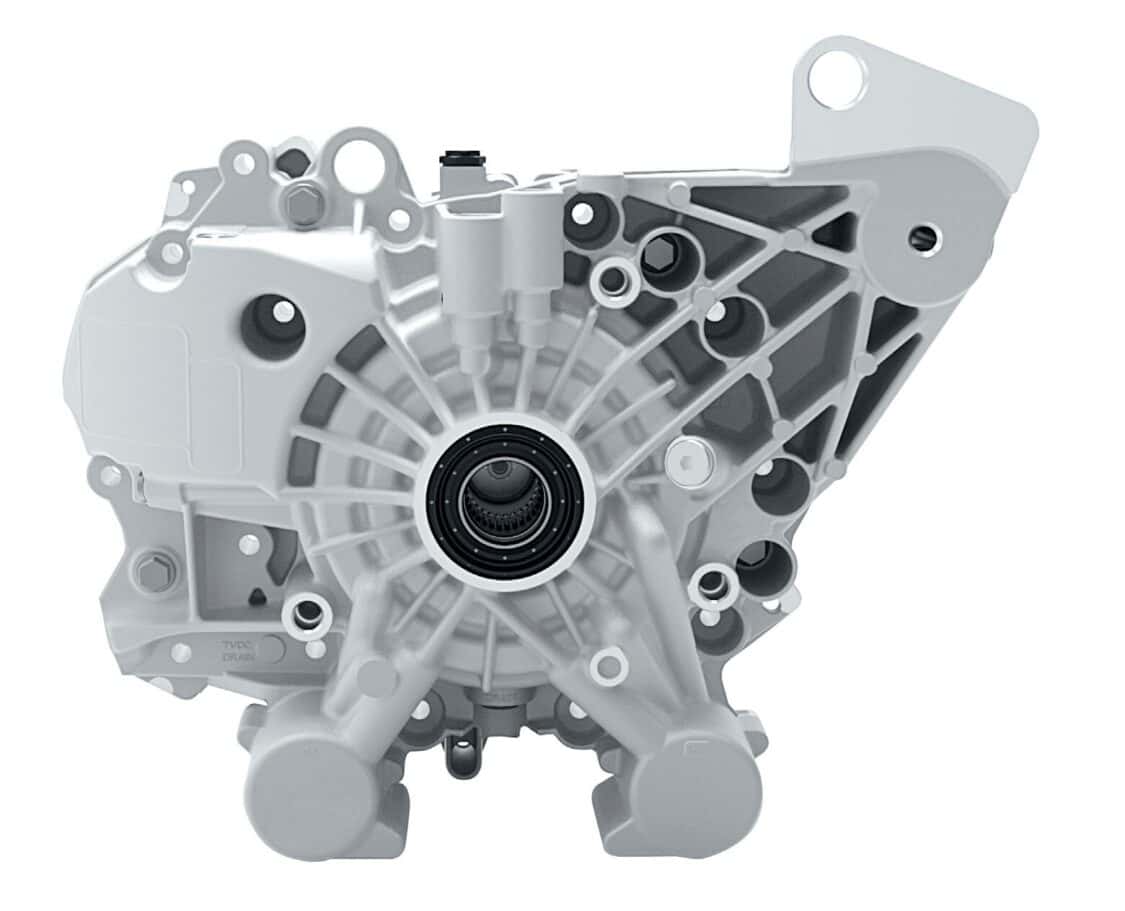

BorgWarner, a global leader in transformative automotive innovation spanning over 130 years, has introduced its latest breakthrough, the Electric Torque Vectoring and Disconnect (eTVD) system. This fancy tech is designed to make electric cars perform better.

ADVERTISEMENT

The eTVD system, a key part of BorgWarner’s electric torque management lineup, uses smart control to make sure wheels have the right amount of power. This helps keep the car stable, improves how it handles, and gives better grip when speeding up or starting. BorgWarner’s eTVD stands out as the first system of its kind to hit the market. It’s already being used in the Polestar 3 SUV, and soon it’ll be in another major European carmaker’s lineup.

“Our new electric vehicle torque management systems showcase our multidisciplinary expertise, system integration capabilities, and the exceptional work of our BorgWarner team,” Weng affirmed, underlining the company’s unwavering dedication to innovation and excellence.

What makes the eTVD special is its all-in-one design, combining three functions into a single system. It replaces the usual differential and adds torque vectoring and an on-demand disconnect feature. This revolutionary setup from BorgWarner changes how electric vehicles will perform.

“In contrast to brake-based systems, torque vectoring through our eTVD minimizes unnecessary brake interventions, thereby mitigating harshness and vibration. This not only prolongs the lifespan of brakes and tires but also contributes to reduced particle emissions,” BorgWarner highlighted, clarifying the environmental and operational advantages embedded in their innovative approach.

ADVERTISEMENT

BorgWarner’s eTVD systems offer flexibility, empowering OEMs to tailor software and controls to align seamlessly with their unique platform requirements and brand identity.

“With the market transitioning to more software-defined modules and vehicles, it is critical to have sophisticated systems in place, like our eTVD, that can precisely and quickly calculate, predict and control vehicle behavior across a wide range of situations,” Weng stated, reiterating BorgWarner’s dedication to remaining at the forefront of technological advancement.

Dealing with the natural hurdle of weight distribution in BEVs, BorgWarner’s eTVD systems transform agility by giving vehicles a lighter, more nimble feel while still ensuring safety isn’t compromised.

“Smart design and intuitive software algorithms minimize the risk of undesired driving characteristics, ensuring superior traction across varying road and weather conditions,” noted BorgWarner, highlighting the system’s adaptability and reliability in real-world scenarios.

At the heart of BorgWarner’s strategy is its unwavering pursuit of excellence, echoed by Weng: “We have received exceptionally positive feedback from customers regarding their test drive experiences and look forward to addressing further market needs with our software, controls, and calibration expertise.”

ADVERTISEMENT

IMAGES: BORGWARNER, POLESTAR, ELECTRIFY EXPO

FTC: We use income-earning auto affiliate links. Learn more.