- Atlas robot can lift up to 110 pounds while operating safely in shared human workspaces.

- Hyundai plans large scale robot production with capacity near 30,000 units annually by 2028.

- Boston Dynamics robots already operate globally, with Stretch unloading over 20 million boxes since 2023.

ADVERTISEMENT

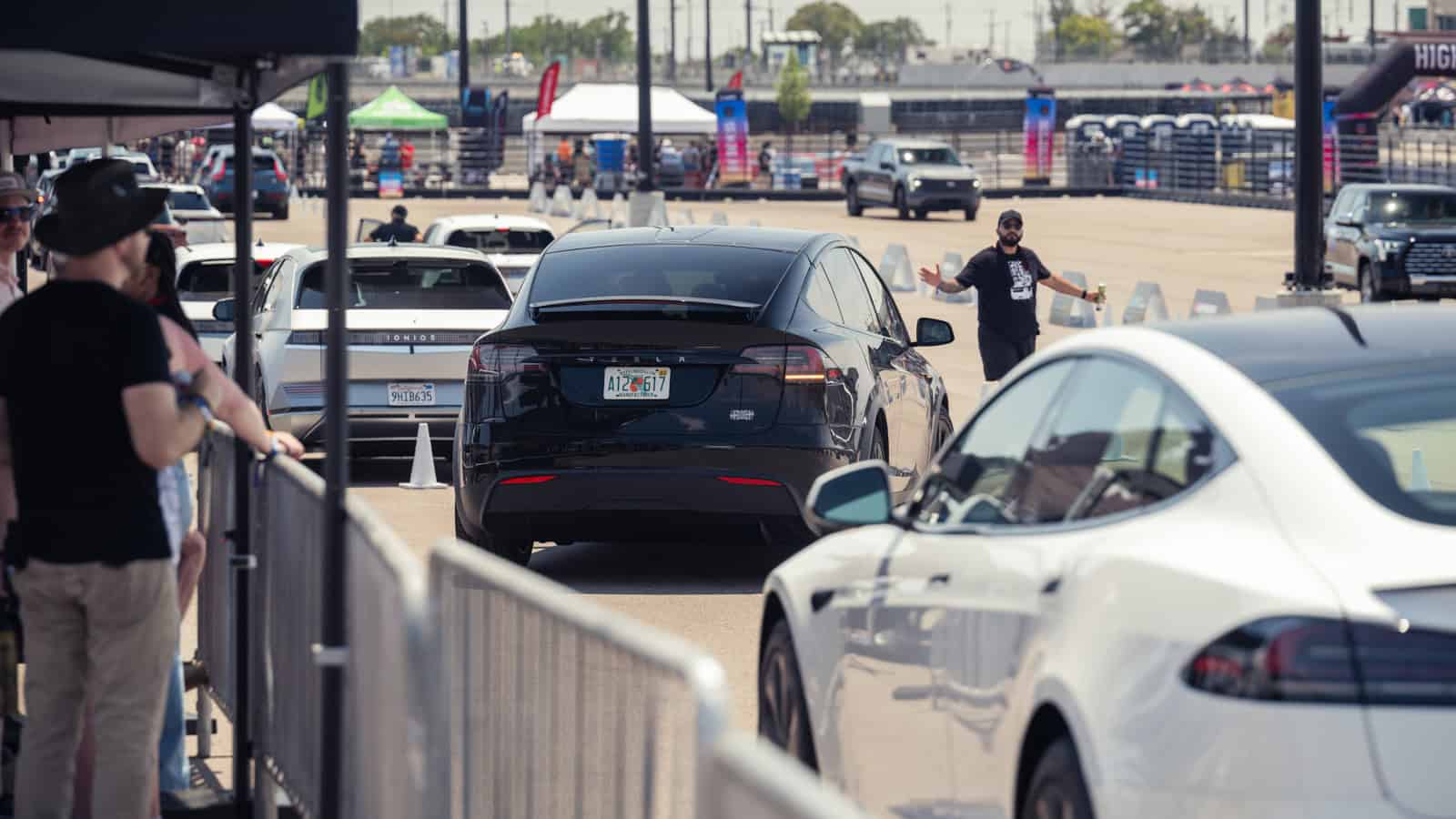

There was a time when robots felt like a science fair trick. Fun to watch. Easy to doubt. Then CES 2026 happened, and Hyundai Motor Group (Hyundai) quietly changed the tone of the room.

At CES in Las Vegas, Hyundai laid out its AI robotics strategy, and the subtext mattered. This was never framed as humans being replaced. The focus stayed on humans staying in control, while machines handle the work that breaks backs, ruins shoulders, or puts lives at risk. That distinction matters. A lot.

Anyone who has walked a factory floor knows the math. Repetitive motion injuries, fatigue, accidents. OSHA data in the U.S. ties musculoskeletal disorders to nearly one third of workplace injuries each year. That number has stayed stubbornly high for decades. No software patch fixes that. Physical help does.

Enter Atlas robot.

Boston Dynamics unveiled its Atlas humanoid robot at CES 2026, and this one feels different. Atlas was built for industrial workspaces that already exist. No dramatic rebuilds. No fantasy environments. Concrete floors, narrow aisles, unpredictable conditions. Real life.

Atlas carries 56 degrees of freedom, human scale hands with tactile sensing, and the strength to lift up to 110 pounds. That number jumps off the page until you realize what it means in practice. Fewer workers wrecking their joints lifting the same load thousands of times per shift. Fewer injuries that follow someone home for life.

ADVERTISEMENT

Training matters too. Most industrial tasks can be taught to Atlas in under a day. That speed removes one of the biggest barriers factories face, downtime. Atlas also manages its own battery swaps and keeps working without constant human babysitting. Independence without chaos.

Boston Dynamics already has proof in the field. Spot operates in over 40 countries, inspecting industrial sites and collecting safety data. Stretch has unloaded more than 20 million boxes worldwide since 2023. Those are shifts completed, day after day.

Hyundai adds scale and discipline to that equation. Automotive manufacturing lives and dies by safety validation, quality control, and repeatability. When Hyundai says Atlas will roll into Hyundai Metaplant America in Savannah, Georgia, starting with sequencing tasks by 2028, the timeline feels measured, careful, and intentional.

That timing matters because the entire plan relies on Physical AI. Real machines gather data from real environments, learn from everyday use, then apply those lessons across factories, logistics, autonomous driving, and robotics. The feedback never stops. Systems improve continuously, while people stay in control and make the decisions.

The Group’s Software Defined Factory system already runs this loop in Singapore and Georgia. Robots learn from production data. Updates flow back into the system. Performance improves without guesswork. This mirrors how modern EV software improves after delivery, except now the learning happens on factory floors.

The Robot Metaplant Application Center, opening in the U.S. in 2026, takes this further. Robots train on mapped human movements like lifts, turns, and recoveries. That training blends simulated data with live operational feedback. And as a result, machines that adapt faster and behave more predictably around people.

ADVERTISEMENT

Hyundai Mobis brings another layer, developing high performance actuators and standardizing components for mass production. Hyundai Glovis tightens logistics. Manufacturing muscle meets robotics R&D without loose ends.

AI infrastructure plays a quiet but critical role here. Hyundai continues its work with NVIDIA to accelerate simulation, training, and deployment. Physical AI demands serious computing power, especially when robots learn in both virtual and real spaces.

Then there’s the collaboration between Boston Dynamics and Google DeepMind. DeepMind’s Gemini Robotics models allow robots to perceive, reason, and interact across changing environments.

Carolina Parada, Senior Director of Robotics at Google DeepMind, said, “We are excited to begin working with the Boston Dynamics team to explore what’s possible with their new Atlas robot as we develop new models to expand the impact of robotics, and to scale robots safely and efficiently.”

Zachary Jackowski, Vice President and General Manager of Atlas at Boston Dynamics, said it even more directly. “The convergence of robotics and AI represents more than a technological advancement. It is a transformative innovation that will make human life safer and more enriching.”

ADVERTISEMENT

That word, safer, keeps coming up. Because this strategy never pretends that robots think like people. Humans still supervise. Humans still decide. Robots lift, carry, inspect, and repeat without fatigue or distraction.

Commercialization stays grounded too. Hyundai plans production capacity near 30,000 robot units annually by 2028. Robots deploy through subscription based Robotics as a Service models already used by DHL, Nestlé, and Maersk. Maintenance, software updates, remote monitoring, all handled centrally. Businesses get predictable costs and faster ROI.

The investment finally matches the ambition. Around $26 billion is going into the U.S. over the next four years, with another KRW 125.2 trillion committed in Korea across five years. That money flows into factories, robotics production, and AI systems. The result creates real jobs while removing people from the kind of work that wears bodies down over time.

At CES 2026, you could watch the idea play out in real time. Atlas handled lifting and sequencing tasks. Spot handled inspections. Stretch kept boxes flowing. MobED rolled through mobility demos. The IONIQ 5 Robotaxi operated calmly through autonomous routines. Nothing felt staged or flashy. It felt like a dry run for what comes next.

ADVERTISEMENT

IMAGES: HYUNDAI MOTOR GROUP

FTC: We use income-earning auto affiliate links. Learn more.