- ENNOVI has introduced a breakthrough in EV battery technology that uses flexible die-cut circuits as a more cost-effective and sustainable alternative to traditional flexible printed circuits.

- This FDC technology streamlines manufacturing by eliminating corrosive chemicals and allows for instant copper recycling.

- This innovation could drive down the costs for EV battery cells and promote more environmentally responsible manufacturing processes.

ENNOVI, a major player in mobility electrification solutions, has unveiled an exciting innovation that could reshape EV battery technology. Called the ENNOVI-CellConnect-Prism, this new technology uses revolutionary types of flexible circuits to enhance performance and sustainability.

ADVERTISEMENT

ENNOVI’s New Flexible Circuits

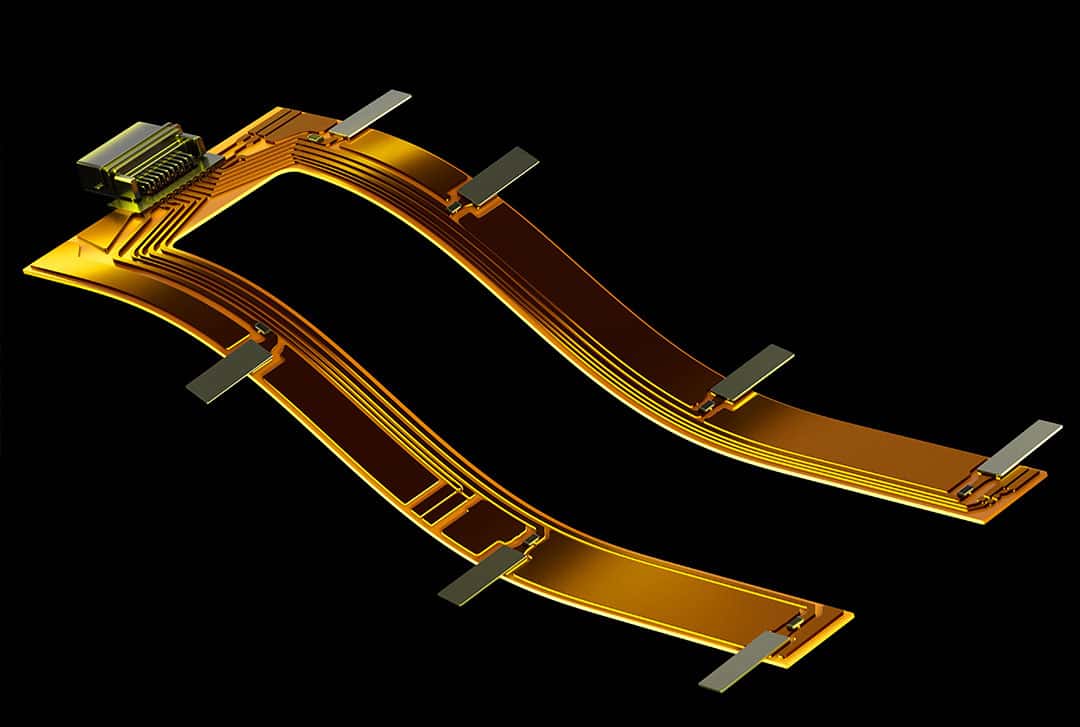

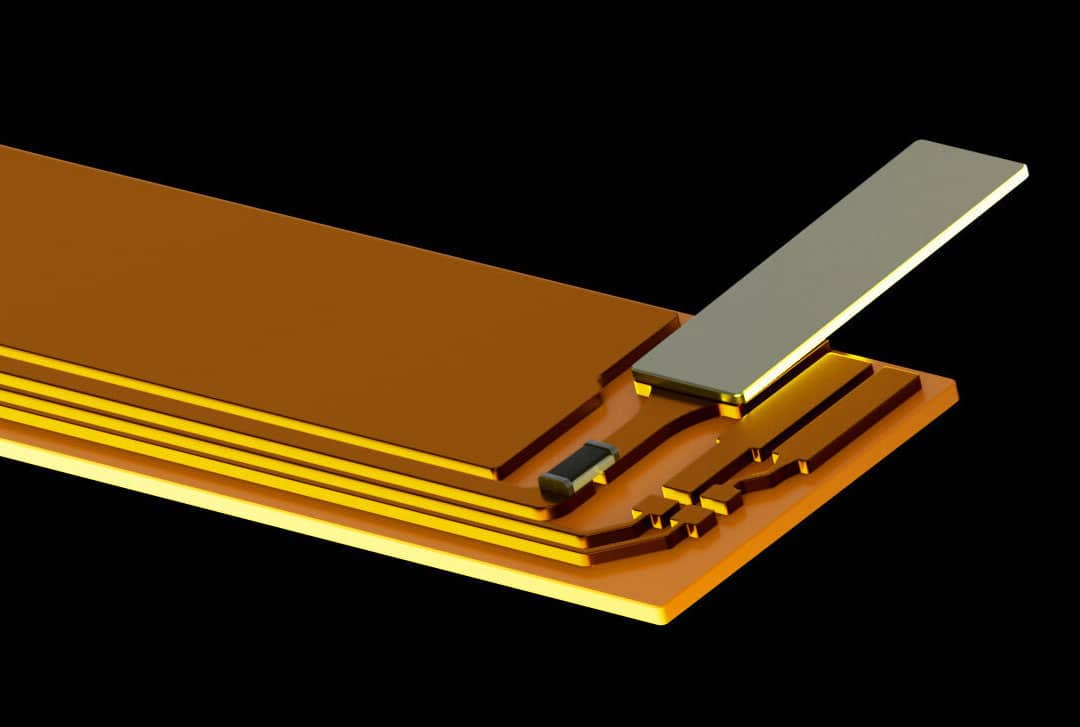

Traditionally, EV battery cell contacting systems use flexible printed circuits. They do work well, but they’re the most expensive component of a collector assembly. Instead of using flexible printed circuits (FPC), ENNOVI has created flexible die-cut circuit (FDC) technology, which is a more cost-effective and eco-friendly alternative when it comes to EV battery manufacturing.

Using FDC technology for flexible circuits streamlines the manufacturing process. FPCs undergo a multi-stage batch photolithography process that involves corrosive chemicals to etch copper traces onto the flexible circuit. Meanwhile, FDCs use a die-cutting process that ends up reducing manufacturing time and allows for an instant recycling of copper.

Prior methods made it a bit challenging to extract copper waste from the etching chemicals and to then recycle the metal. By eliminating the need for those corrosive chemicals, the leftover copper can be reused more easily for the next project, making the entire process more efficient and sustainable.

Plus, FDCs do away with the size restrictions of FPCs, which are limited to 600 mm x 600 mm. Because FDCs are manufactured reel-to-reel, they have flexibility in their size and shape without compromising on performance. They’ve already been tested in-house to make sure they can withstand thermal shock, temperature fluctuations, insulation resistance, and high voltage.

ADVERTISEMENT

What This Innovation Could Mean for EVs

“Adopting the FDC capability for flexible circuits aligns with our vision to think outside the box in creating a sustainable battery value chain for EVs,” explained Gustavo Cibrian, who is the Product Manager, Energy Systems at ENNOVI.

By offering battery manufacturers a versatile current collector assembly design solution that prioritizes cost, performance, and time, ENNOVI’s FDC technology allows them to design to cost and potentially lower the prices of EV battery cells in the future.

These new flexible circuits can also mean a more environmentally responsible approach to making EV batteries, and thus EVs. They reduce manufacturers’ reliance on chemical-intensive processes and promote efficient copper recycling.

Overall, because questions still abound about how eco-friendly EVs truly are, any steps toward making more sustainable manufacturing processes are a good thing.

ADVERTISEMENT

FEATURE IMAGE: MINGWEI LIM

FTC: We use income-earning auto affiliate links. Learn more.