- BMW is testing all-solid-state batteries (ASSBs) in a BMW i7 prototype in Munich, developed in collaboration with Solid Power.

- These ASSBs utilize a sulfide-based solid electrolyte, offering higher energy density and improved safety over traditional lithium-ion batteries.

- BMW and Solid Power have been collaborating since 2016, with BMW investing in Solid Power and operating a prototype line at its Cell Manufacturing Competence Center in Parsdorf.

ADVERTISEMENT

They said it couldn’t be done. A battery with no liquid, no leaks, and no limits. But BMW and Solid Power are doing it anyway.

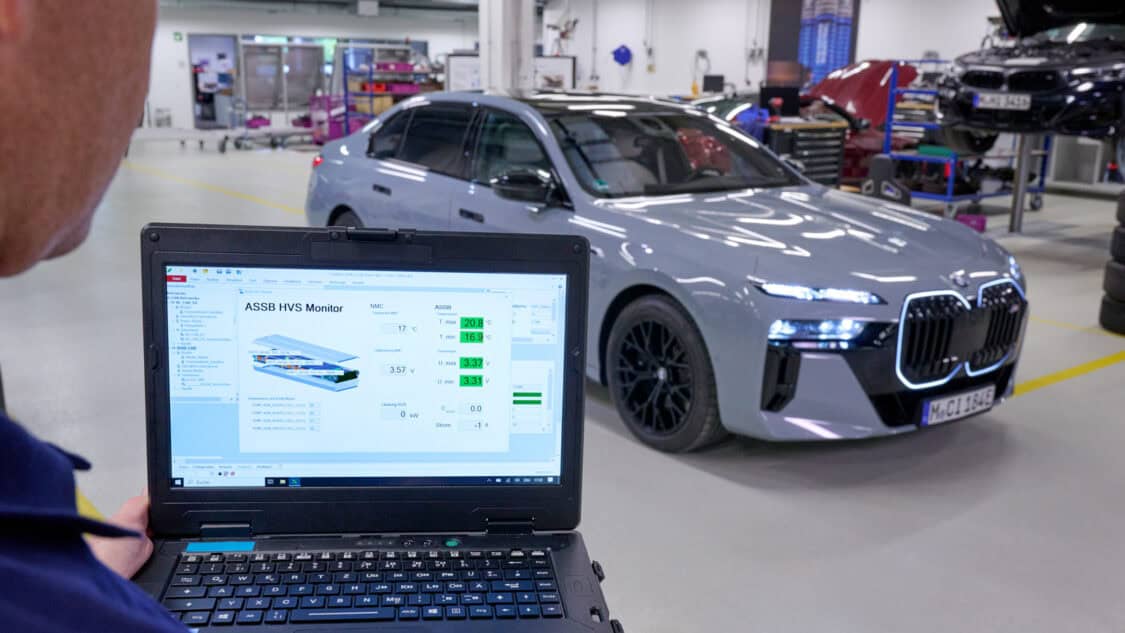

In Munich, BMW is currently testing its i7 prototype to evaluate both performance and the potential future of electric vehicle (EV) battery systems. This test involves more than typical range or acceleration benchmarks. The i7 has been equipped with all-solid-state batteries (ASSBs), which were developed through a collaboration with Solid Power, a company that has been focused on advancing battery technology since it was founded in 2011.

So, what’s the big deal with ASSBs? Traditional lithium-ion batteries use liquid electrolytes, which can pose safety risks and limit energy density. Solid Power’s ASSBs replace this liquid with a sulfide-based solid electrolyte, improving safety and allowing for higher energy density. This means longer driving ranges and potentially faster charging times.

John Van Scoter, President and CEO of Solid Power, expressed his enthusiasm by stating, “Solid Power is extremely proud that our partnership with BMW has resulted in the first demonstration of truly all-solid-state battery cells in a vehicle. We believe in the promise of ASSBs and continue to drive innovation of our sulfide electrolyte in support of that future for EVs” .

ADVERTISEMENT

BMW has a long history of working in battery cell technology. Since 2008, the company has expanded its knowledge in this field through continuous research and technical development. In 2019, BMW brought that experience together at the Battery Cell Competence Center (BCCC) in Munich, where teams focus on everything from design and chemistry to production capabilities.

Its collaboration with Solid Power, which started in 2016, has deepened that expertise and added another layer of real-world application to BMW’s growing electric vehicle efforts.

The i7 test vehicle uses BMW’s Gen5 construction principles along with updated module concepts specifically designed to support all-solid-state battery cells. This approach goes beyond simply placing a different battery into an existing structure.

Engineers are developing an entirely new battery system that can support the physical and chemical requirements of solid-state cells. Their work focuses on controlling how the battery cells expand, managing internal pressure, and maintaining stable temperature conditions to ensure the system performs reliably under a wide range of driving environments.

But BMW isn’t the only automaker investing in solid-state battery technology. Mercedes-Benz has also entered this space by working with Factorial Energy to test lithium-metal solid-state batteries in a modified EQS. The goal of this collaboration is to achieve a driving range of over 600 miles while reducing battery weight by 40 percent compared to today’s standard lithium-ion batteries.

Although solid-state batteries offer tremendous potential, there are still several challenges that need to be addressed. Companies like Solid Power and BMW are currently focused on scaling up production, improving battery lifespan, and making the technology more affordable. With continued testing and collaboration, EVs powered by solid-state batteries are becoming a more realistic option for the future.

ADVERTISEMENT

SOURCE I IMAGES: BMW

FTC: We use income-earning auto affiliate links. Learn more.