- Many EV motors require magnets made from rare earth elements, which are ecologically damaging to mine.

- Tula Technology is working to perfect an EV motor control that doesn’t use rare earth elements without sacrificing efficiency.

- The company is currently testing its concept on a Chevy Bolt and a Tesla Model 3.

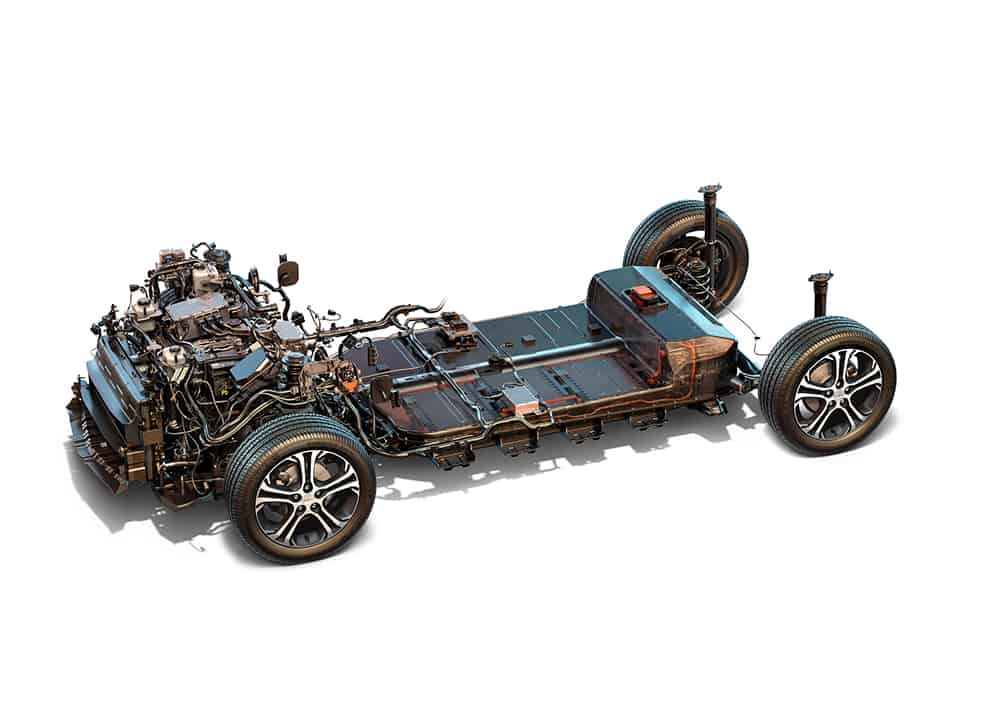

In 2021, Tula Technology drew attention to the reliance the EV industry has on rare earth elements (REEs) for manufacturing magnets – crucial components in traditional EV production. These materials not only cause significant environmental damage during their extraction but also present challenges related to supply and cost. Recognizing the risks associated with REEs, industry leaders are now advocating for reduced dependence on these magnets. And Tula Technology has developed an EV motor that avoids the use of permanent magnets, avoiding having to use rare earth elements.

How Damaging Are Rare Earth Elements?

While REEs aren’t truly scarce in nature, they are rarely found in concentrations that make their extraction environmentally or economically viable. According to a 2021 report from the Harvard International Review, producing the rare earth magnets required for a single EV generates three tons of toxic waste.

Increased scrutiny has fallen on mining practices because of their environmental impact, but the demand for REEs has surged with the growth of electric propulsion. Expanding mining capacity is unsustainable, but on the other hand, failing to mine more REEs is economically unfeasible.

Tula Technology’s New Motor Development

To combat these issues, Tula Technology has been pushing for advancements in electric motor control to improve the efficiency of EVs that don’t rely on permanent magnets. Tula’s Dynamic Motor Drive (DMD®) utilizes proprietary control algorithms to achieve industry-leading efficiency when paired with externally excited synchronous motors (EESM).

This type of motor eliminates the need for permanent magnets, and OEMs worldwide have started adopting this technology to avoid REEs and lower their system costs. It’s significant to note that DMD enhances the efficiency of these rare-earth-free powertrains beyond what would normally be achievable with the best permanent magnet motors.

A Move Away From Rare Earth Elements

R. Scott Bailey, Tula’s President and CEO, is glad to see the industry’s growing consensus on this issue, stating, “Eliminating the dependence on rare earth elements not only brings down the cost of EVs, thereby making them more accessible, it also eases concerns about the environmental challenges associated with rare earth elements.”

Bailey highlighted the impact of Tula’s DMD software, stating, “Our DMD software solution improves system efficiency by two to three percent in EESM applications and lowers total cost.”

To look at this another way: By 2030, the global EV fleet is projected to consume 750 billion kilowatt hours of electricity. With a 3% savings, valued at over $3.4 billion annually at current rates, the energy savings could eliminate the need for approximately five coal-fired power plants.

For a proof of concept, Tula implemented DMD into a Chevrolet Bolt. It’s not undergoing tests at independent, third-party labs to validate Tula’s claimed efficiency gains. Tula is also developing an EESM powertrain that they’ll install inside an existing Tesla Model 3.

Bailey emphasized the crucial role of EVs in achieving net-zero emissions by 2050, stating, “For truly sustainable transportation, an alternative to rare earth elements is needed. This is where the market is headed, and this is where Tula is focused.”

SOURCE | IMAGES: TECHDOGS | USGS, CHEVROLET

FTC: We use income-earning auto affiliate links. Learn more.