- Honda’s demonstration line spans 27,400 square meters and will begin producing solid-state batteries in January 2025.

- The roll-pressing technique increases electrolyte density and reduces production time, improving battery performance and cost efficiency.

- Honda plans to use solid-state batteries across cars, motorcycles, and aircraft to drive down costs through economies of scale.

ADVERTISEMENT

Solid-state batteries may be the key to unlocking the next era of electric cars, offering solutions to challenges like limited range, long charging times, and high costs that have held back broader adoption.

With their higher energy density and superior heat resistance, these batteries have the potential to deliver electric vehicles (EVs) with ranges exceeding 500 miles per charge, which is ideal for road trips and everyday use.

The automotive industry is changing fast, and Honda’s newly introduced demonstration production line in Sakura City, Tochigi Prefecture, Japan, highlights how battery technology is evolving.

ADVERTISEMENT

Keiji Otsu, President and Representative Director of Honda R&D Co., Ltd., described this breakthrough, “The all-solid-state battery is an innovative technology that will be a game changer in this EV era. Replacing engines that have been supporting the advancements of automobiles to date, batteries will be the key factor of electrification. We believe that advancement of batteries will be a driving force in the transformation of Honda. Now, the start of operation of our demonstration production line for our all-solid-state batteries is in sight, and we can say that we have reached an important milestone for Honda and the country of Japan.”

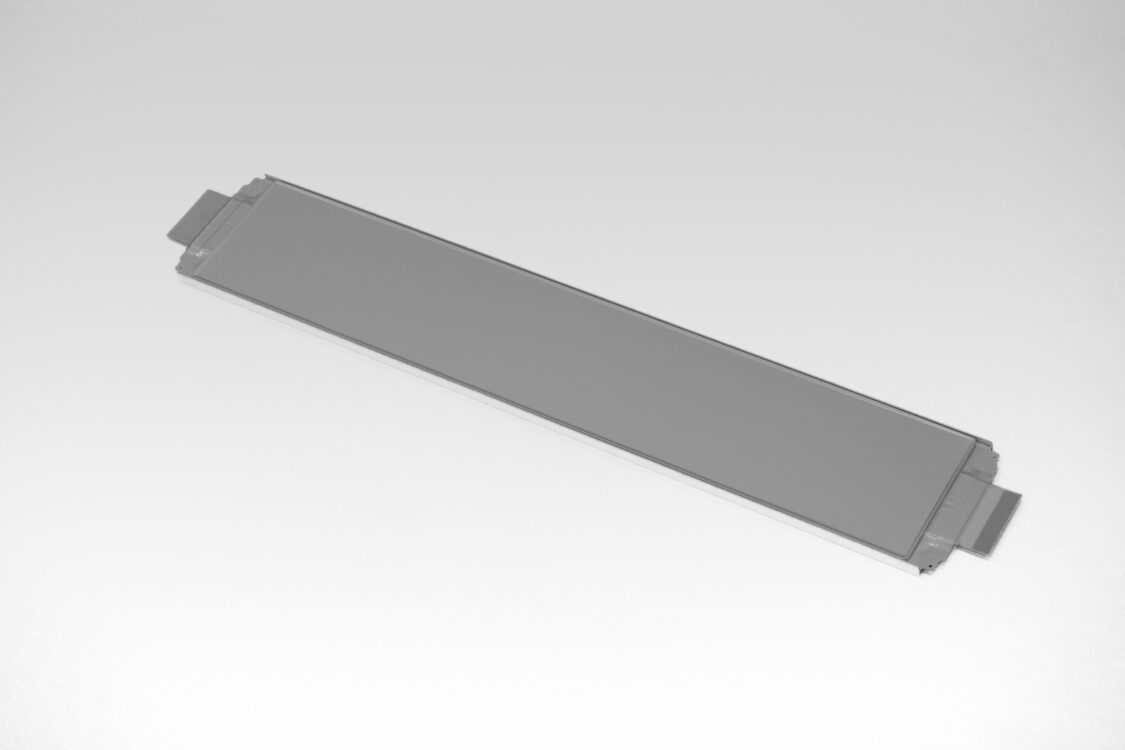

This facility, spanning 27,400 square meters, is equipped with advanced systems to weigh and mix materials, assemble battery modules, and streamline the creation of cells. Honda is integrating new techniques such as roll-pressing to improve the density of electrolyte layers, boosting efficiency and performance while cutting production time.

By January 2025, the facility will begin fine-tuning battery specifications and developing cost-effective production methods, setting the stage for the next generation of electric vehicles.

Unlike traditional lithium-ion batteries that rely on liquid electrolytes, solid-state batteries use a solid electrolyte. This design delivers higher energy density, greater heat resistance, and improved durability. Honda is driving progress in this area, addressing these issues directly to create more affordable, efficient, and reliable batteries for everyday use.

ADVERTISEMENT

As Otsu stated, “We will continue taking on challenges to launch our mobility products equipped with our all-solid-state batteries as quickly as possible so that Honda can offer new value to our customers.”

Honda plans to expand its solid-state battery technology to motorcycles, aircraft, and other vehicles, bringing this advancement to a variety of industries.

By scaling production and leveraging economies of scale, Honda is working to make solid-state batteries more affordable and accessible. Additionally, the company is tackling indirect costs, such as power consumption, by creating controlled environments that optimize both safety and performance during assembly.

Solid-state batteries are central to Honda’s long-term goal of achieving carbon neutrality for all its products and corporate activities by 2050. Simplified cooling systems and streamlined production processes further support this mission by reducing costs without compromising performance.

ADVERTISEMENT

As competition in the race for next-generation EV batteries heats up, Honda’s focus on solid-state technology highlights its commitment to advancing the field. By beginning the production process even before finalizing battery specifications, the company accelerates development timelines and focuses on real-world applications that benefit consumers directly.

Honda’s proven expertise in advancing technologies like fuel cells and solar cells adds credibility to its work in the field of solid-state battery innovation. As Keiji Otsu explained, these advancements go beyond technical achievements. They reflect Honda’s dedication to advancing electric mobility and delivering meaningful benefits to its customers.

ADVERTISEMENT

SOURCE | IMAGES: HONDA

FTC: We use income-earning auto affiliate links. Learn more.