- GM’s new EV batteries use a lithium manganese-rich (LMR) formula with 65% manganese, cutting cost and reducing cobalt dependency.

- Prismatic cell design reduces battery module components by 75% and total pack parts by 50%, improving efficiency and scalability.

- LMR technology delivers 33% higher energy density than LFP at comparable cost, enabling trucks with over 400 miles of range.

ADVERTISEMENT

What if the next big thing in EV batteries wasn’t some mysterious supermaterial from a secret lab, but a technology that’s been sitting on the shelf since the 90s, just waiting for someone to fix it?

General Motors (GM), along with LG Energy Solution, says they finally cracked the code on something called LMR batteries. That’s lithium manganese-rich, for those who don’t speak fluent electrochemistry. And yes, it’s kind of a big deal without trying to sound dramatic.

For years, LMR batteries were treated like the awkward understudies of EV technology. On paper, they had everything from long driving range, lower costs, and promising chemistry. But in practice, they fell short. The battery life was too brief, and they lost voltage too quickly over time. Despite their potential, they simply could not deliver the performance needed for real-world driving. So, they were sidelined.

But here’s where things get interesting. According to Kushal Narayanaswamy, GM’s Director of Advanced Battery Cell Engineering, “GM and our collaborator LG Energy Solution have engineered solutions clearing the way for a leap forward that will offer consumers EVs with an attractive combination of long range and low cost.” In other words, a battery technology that was once considered impractical might now be ready to outperform expectations.

And GM isn’t building this alone. LG Energy Solution has been developing this chemistry for over a decade, holding a deep library of technical knowledge, with more than 200 patents around LMR tech globally.

ADVERTISEMENT

As EVP Wonjoon Suh explained, “GM’s future trucks powered by this new chemistry are a strong example of our shared commitment to offering diverse EV options to consumers.”

Together, they’ve brought this battery design from theory to production, with the kind of experience and technical depth that doesn’t come out of nowhere.

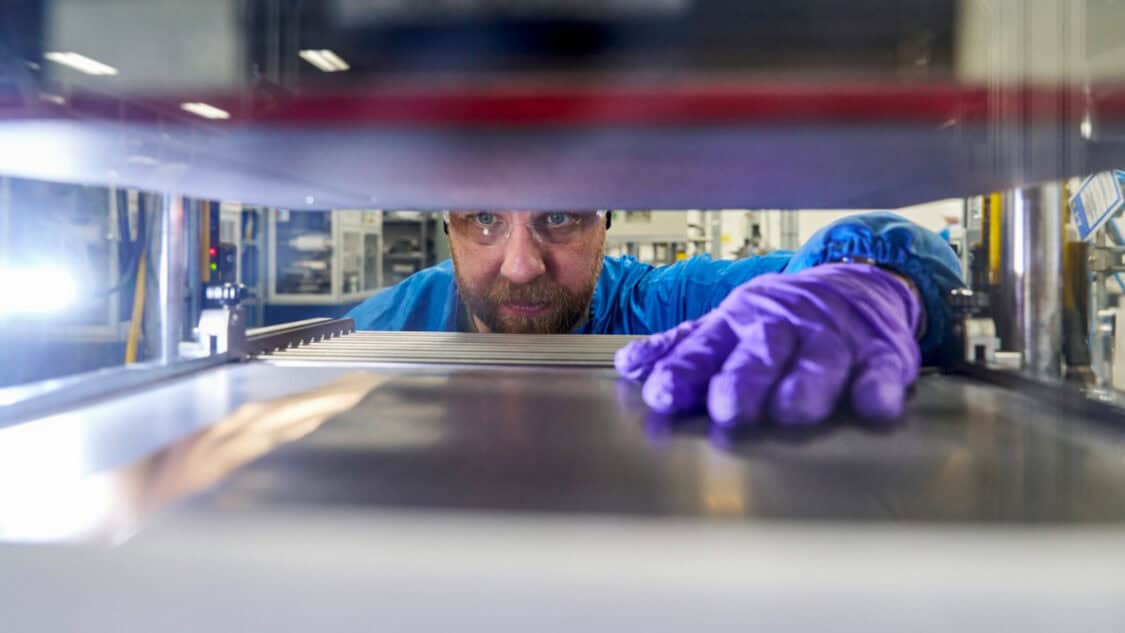

By the end of 2024, GM had already completed extensive testing. Engineers at the Wallace Battery Cell Innovation Center coated approximately one ton of lithium manganese-rich cathode material and used it to create a wide range of prototype prismatic cells, 18 different types across three cell dimensions.

These cells were then tested to perform under conditions equivalent to 1.4 million miles of electric vehicle driving. These results weren’t based on projections, they came from direct testing and real-world validation.

So what makes these new EV batteries different from what’s already on the road? Right now, GM’s EVs, like the Silverado EV Work Truck with Max Range, use high-nickel batteries called NMCA (nickel manganese cobalt aluminum oxide). They’re powerful, but expensive. Nickel and cobalt are pricey, volatile, and tough to ethically source.

Compared to traditional battery chemistries, LMR batteries contain approximately 65% manganese and 35% nickel, with almost no cobalt. Manganese is less expensive, more widely available, and does not carry the same geopolitical complications as cobalt. This composition lowers the overall material cost of the battery. Additionally, LMR batteries deliver 33% greater energy density than lithium iron phosphate (LFP), a lower-cost option currently used by companies like BYD and Tesla in select models.

And those batteries? They’re going rectangular.

GM is replacing the current pouch-style battery cells with a prismatic form factor. These new cells are rectangular, similar to bricks, and are designed to be packed more efficiently within the vehicle. Because they require fewer components, there are fewer potential failure points. This streamlined structure also helps reduce manufacturing complexity and overall cost, making the battery packs more scalable for production.

According to General Motors, using LMR prismatic battery cells results in a 75 percent reduction in battery module components and a 50 percent reduction in total pack components. This change simplifies the battery system architecture by reducing the number of parts involved, which can improve manufacturing efficiency and lower production costs.

Kurt Kelty, GM’s Vice President of Battery, Propulsion, and Sustainability, explained, “We’re pioneering manganese-rich battery technology to unlock premium range and performance at an affordable cost, especially in electric trucks.”

ADVERTISEMENT

But here’s the question that probably popped into your head somewhere around paragraph five: When can I get one?

Fair. GM says commercial production of these new LMR prismatic battery cells will begin in the U.S. by 2028, through Ultium Cells, GM and LG’s joint venture. Pre-production kicks off at LG’s facilities in late 2027, with validation happening at GM’s upcoming Battery Cell Development Center in Warren.

For now, GM offers the longest-range electric truck available. The Chevrolet Silverado EV Work Truck with Max Range is officially rated by the EPA at 492 miles on a full charge. It also has the fastest charging capability in its class, with a peak rate of 350 kilowatts.

This development is not only focused on increasing range but it also addresses the high cost of electric vehicles, trucks, SUVs, and others, which continues to be a major barrier for many buyers. Right now, price (and interest rates) remains one of the biggest reasons consumers hesitate to make the switch to electric. GM has been working behind the scenes for nearly a decade to change that reality.

It’s also worth noting that GM’s not the only one experimenting here. Tesla continues to double down on its LFP batteries for affordability. Ford is exploring manganese-based chemistries in its long-term EV plans. But no one else, yet, is going all-in on LMR like GM.

So why does this matter? Because EV battery technology is the foundation of electric vehicle progress. If LMR batteries can finally live up to their decades-old potential, that could lead to more affordable electric vehicles, longer driving range, and a reduced need for materials that are expensive, difficult to source, and often controversial.

Look, we’re not saying this is going to solve every EV problem overnight. But if GM really delivers an electric truck with over 400 miles of range at a lower cost, people are going to notice. And maybe, just maybe, those LMR nerds from the ’90s finally get their moment.

Here’s what to keep in mind going forward:

- Watch GM’s Battery Cell Development Center in Warren, Michigan. It’s going to be the heart of this next-gen battery rollout.

- Keep tabs on Ultium Cells. Once 2028 hits, you’ll likely see these LMR batteries in full-size electric trucks and SUVs.

- And if you’re shopping for an EV down the line, don’t just ask how long do EV batteries last. Ask what chemistry they’re using. Because chemistry matters. Big time.

You wanted longer EV range and lower prices? You might just get both. And that, my friend, is something everyone should know.

ADVERTISEMENT

SOURCE | IMAGES: GENERAL MOTORS

FTC: We use income-earning auto affiliate links. Learn more.