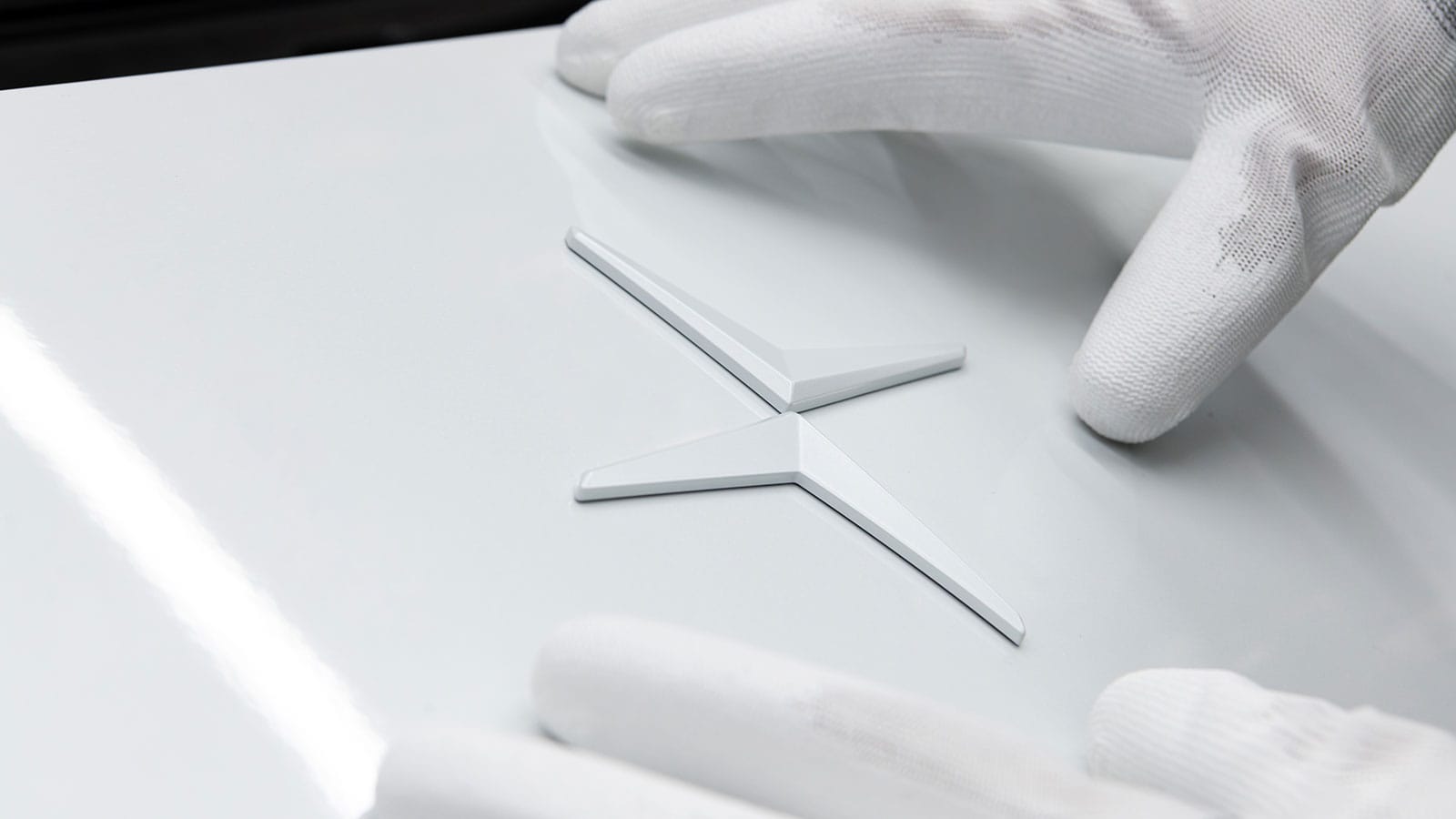

Polestar is ramping up its recycling efforts with a new partnership that it believes will make EV manufacturing cleaner and greener.

Swedish performance EV brand Polestar is partnering with Cyclic Materials, a Kingston, Ontario-based magnet recycling startup that’s working to develop a circular supply chain for rare earth magnets in an effort to reduce the overall environmental impact of manufacturing an electric vehicle.

The companies signed a memorandum of understanding (MOU) last month after, Polestar committed to recycling rare earth metals from its vehicles’ end-of-life electric motors and use them for new vehicles, instead of mining for virgin rare earth minerals.

“Magnet [recycling] seems to be something we’ve overlooked or the industry has overlooked,” says Sander Jahilo, circularity lead at Polestar in an interview with Electric Autonomy. “We think this is something that we can have a direct impact on because a lot of rare earth elements-based magnets are being put in the market, but it’s all going to waste. This seems almost outrageous and [something] we need to solve.”

As part of the MOU with Cyclic, Polestar plans to test the recycled magnets supplied by the Canadian firm in real-world applications, ensuring that they’re able to offer performance that’s “good as new” with a much lower their raw material footprint.

“We’ll see what the results of that are but we are quite hopeful right now that we can incorporate those magnets into our future cars from 2025 onwards when Cyclic Materials scales up,” says Jahilo.

The move is part of Polestar’s larger “Polestar 0” project, which promises a truly carbon-neutral car by 2030. It’s worth noting that the brand aims to eliminate emissions, not merely offset them by planting trees or buying credits.

“Offsetting is a cop-out,” says Thomas Ingenlath, Polestar CEO. “By pushing ourselves to create a completely climate-neutral car, we are forced to reach beyond what is possible today. We will have to question everything, innovate, and look to exponential technologies as we design towards zero.”

The company plans to build its first commercial plant in Kingston later this year, with plans to produce 600 tons of recycled rare earth oxides by 2026, increasing to 3,000 tonnes annually by 2030.

SOURCE | IMAGES: POLESTAR, VIA ELECTRIC AUTONOMY.

FTC: We use income-earning auto affiliate links. Learn more.