- China is leading the way with research and development of sodium-ion batteries.

- The US has the largest cache of soda ash needed for sodium-ion battery production.

- Sodium-ion batteries are safer than lithium-ion batteries.

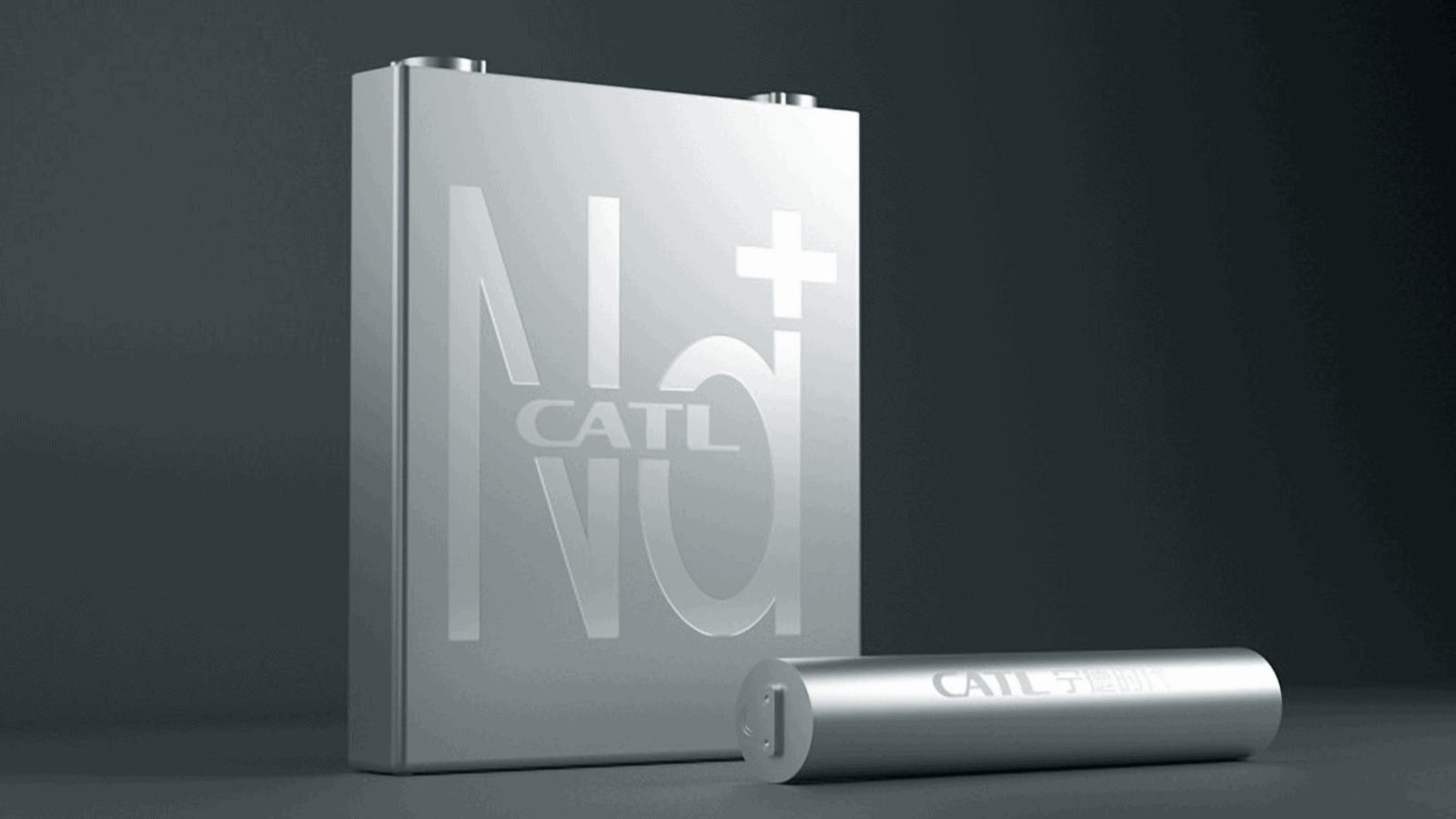

As more drivers turn to electric cars, automakers and battery manufacturers are looking for alternatives to expensive lithium-ion batteries. The newest and more eco-friendly alternative is coming from China’s largest battery producer: Contemporary Amperex Technology Co. Limited (CATL), and it’s in the form of sodium-ion batteries.

CATL began investing in sodium-ion batteries, and it plans to begin producing the batteries for an industrial supply chain in 2023. While CATL sodium-ion batteries won’t yet be available for electric vehicles, this could change sooner rather than later.

Sodium-Ion Battery Technology

CATL sodium-ion batteries function the same way as lithium-ion batteries. They both create electricity through the chemical reactions occurring between the anode, cathode, and electrolyte. Rather than using lithium ions, sodium ions move through the electrolyte.

For decades, industries have used sodium-ion batteries, but they haven’t been considered for EVs because they don’t provide the same range as their lithium-ion counterparts. However, manufacturers are taking a second look because sodium battery technology is less expensive than lithium-ion tech.

Sodium and lithium have similar qualities, but sodium is more abundant. It’s easier to source than the costly procedure of mining lithium. Sourcing lithium does not cause damage to drinking water sources.

Benefits of Sodium-Ion Batteries

Lithium-ion batteries require expensive raw materials like cobalt, copper, and lithium. These materials require mining in eco-sensitive areas. Sodium-ion batteries do not require the same raw materials, so they are less expensive to manufacture. While it’s possible to recycle lithium-ion batteries, it’s much easier to recycle sodium-ion batteries making them a reliable source of energy for generations.

Lithium currently costs over $80,000 per metric ton, while sodium is under $300 per metric ton. Unfortunately, Na-ion batteries do not have the same energy reserves as Li-ion batteries, so they struggle to support performance EVs from automakers like Tesla and Kia. On the flip side, Li-ion batteries have “thermal runaway’ which can cause the batteries to catch fire. Na-ion batteries do not do this, which is one reason why manufacturers are dedicated to developing this product.

Overall, sodium-ion batteries have several benefits when compared to Li-ion batteries:

- Less expensive to manufacture

- Function efficiently in low temperatures

- Enhanced safety features

Sodium-Ion Batteries and Compact EVs

BYD and CATL expect to begin selling their Na-ion batteries in 2023 at the current price of $77 per kilowatt hour. Experts predict the cost will drop to $40 per kWh. They have the potential to become a viable alternative, and CATL will use them to power EVs. BYD will also mass-produce sodium-ion battery technology and will put the batteries in a compact EV.

At the Shanghai Auto Show, CATL announced they will put their Na-ion batteries in the Chery i-Car in 2023, and BYD will sell the Seagull with the sodium-ion blade batteries by the end of the year. The BYD vehicle will have a sticker price between $11,000 and $14,000.

The new versions will use a blade battery with 30.08 kWh and 38.88 kWh. Because Na-ion batteries do not have as much power as Li-ion batteries, more batteries are needed in EVs. At this time, sodium-ion batteries are better suited for compact SUVs with minimal horsepower.

Developing Sodium-Ion Technology

The lower energy density batteries makes them ideal for grid-battery storage, so utility companies could install more Na-ion batteries in a minimal amount of space. Sodium-ion technology could become standard in public EV charging stations, as it could reduce strain on the electrical grid.

China continues its dominance over the battery industry by being the major manufacturer of sodium-ion batteries. In the next few years, it will have almost 95% of battery production. However, China has one major challenge: limited access to soda ash.

The US has over 90% of soda ash buried in the desert in southwest Wyoming. This resource is most often used for glass production, but it could help the US become a major player in Na-ion battery production. Unfortunately, the US is lagging in its dedication to researching battery technology, despite having the natural resources to support it.

The EV industry could be on the cusp of a major change because sodium-ion battery technology will make EVs more affordable and accessible. The biggest challenge is the decrease in performance over time, but Na-ion batteries do not have the same degradation as Li-ion. As more research goes into sodium-ion batteries, new tech is on the horizon making this industry one to watch.

SOURCE | FEATURE IMAGE: CATL | BYD

FTC: We use income-earning auto affiliate links. Learn more.

3 Responses

Hi – can these batteries be used succesfully in golf carts – 48volt.

How will profitable for solar hybrid system